Supply chain performance shapes how fast you deliver, how much you spend, and how reliable your promises feel to customers. The good news is that most bottlenecks can be improved with practical steps that do not require a full overhaul.

Set clear goals and map the end to end flow

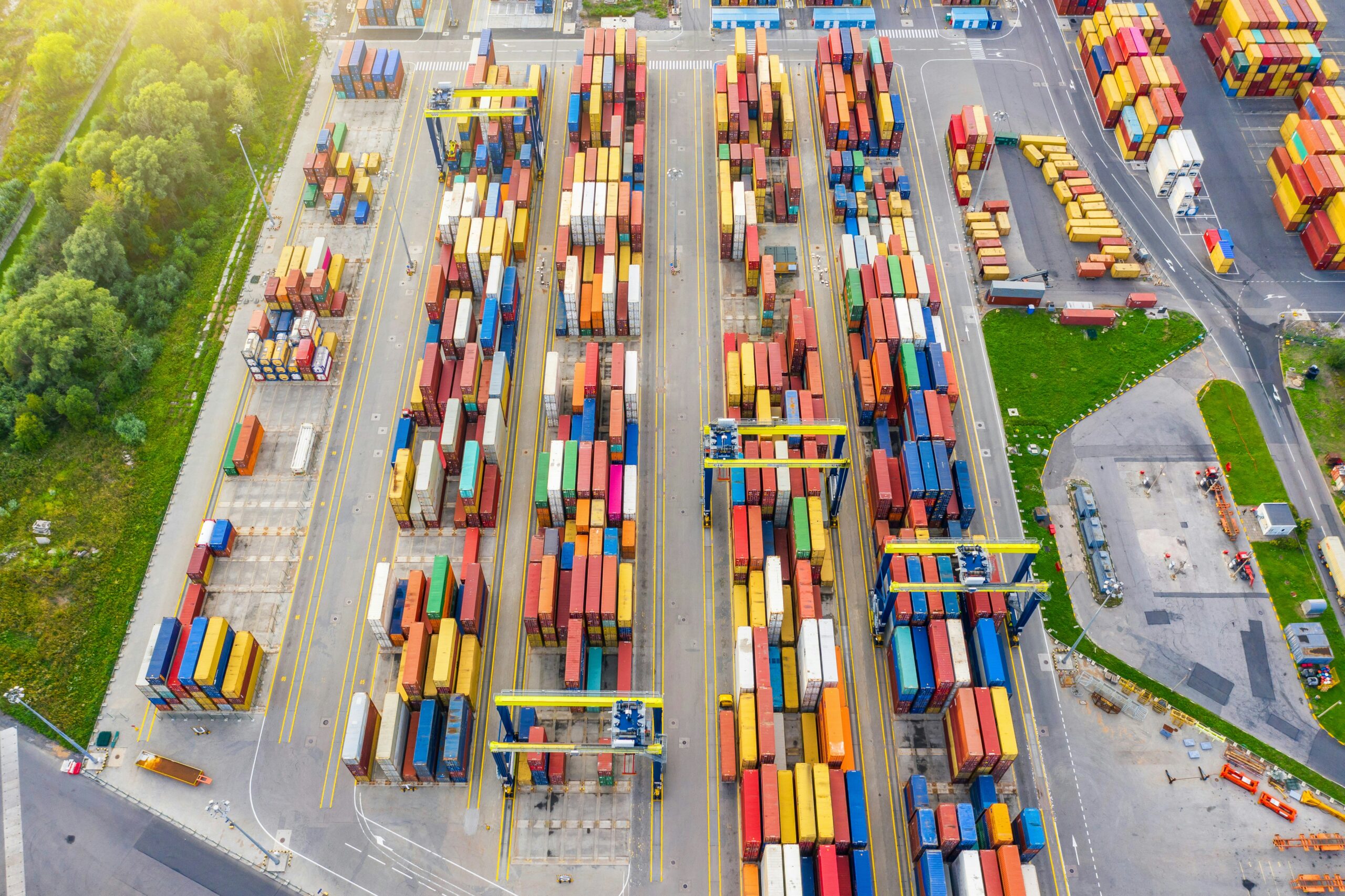

- Source: searchxpro.com

Before changing anything, define what “better” means for your business, because each goal points to different actions. Typical targets include shorter lead times, higher delivery reliability, lower inventory, and reduced logistics cost.

Start by mapping the full flow from suppliers to the final customer, including information as well as physical movement. Mark every point where materials wait, are handled twice, or travel without adding value, because those spots usually hide the largest losses.

Convert the map into measurable priorities using a small set of KPIs such as OTIF, inventory turns, forecast accuracy, capacity utilization, and cost per unit shipped. If you want an external benchmark or help translating findings into a focused roadmap, Learn more about supply chain consultancy can be a useful reference, but keep the internal ownership of goals and metrics.

Once KPIs exist, set a baseline and agree on a cadence for review, weekly for operational metrics and monthly for strategic ones. Make sure each metric has a clear owner and a defined action when it moves outside tolerance.

Improve planning, inventory, and supplier collaboration

- Source: brianokanecalgary.com

Planning is the nerve center of the supply chain, so small accuracy gains create big downstream benefits. Bring sales, marketing, finance, and operations into a regular S and OP or IBP cycle so everyone works from one demand picture.

Use a rolling forecast that is updated frequently, and track error by product family and region to learn where demand is most volatile. Instead of trying to be perfect everywhere, focus forecasting effort on high value or constrained items and simplify the rest.

Inventory should be segmented by role, not treated as one big pile. Identify safety stock for variability, cycle stock for normal replenishment, and strategic buffers for risk, then set different rules for each.

Replenishment policies also matter, so review order frequency, minimum order quantities, and lot sizes to avoid artificial spikes. When possible, shift from push to pull for stable items, using visual signals or system triggers to refill based on actual consumption.

Suppliers are part of your system, not a separate world, so share forecasts and constraints early. Build scorecards that include quality, lead time, and responsiveness, then hold joint improvement sessions on the few partners that drive most of the spend or risk.

Strengthen execution with data, standard work, and resilient logistics

- Source: business-reporter.com

Even the best plan fails without disciplined execution, so standardize critical routines on the floor and in the warehouse. Clear work instructions, visual controls, and realistic takt times reduce variation far more than heroic firefighting.

Data should support decisions at the same speed as operations. Connect ERP, WMS, TMS, and supplier portals so planners and supervisors see one version of truth on orders, inventory, and capacity.

Automate alerts for exceptions like late inbound shipments, stockouts, or capacity breaches, and assign owners to resolve them within defined time windows. Pair that with root cause analysis, such as 5 Whys or fishbone diagrams, to prevent repeat issues.

Logistics networks benefit from regular tuning rather than rare reinventions. Review transport modes, lane utilization, and warehouse locations yearly, and run small pilots to test changes before scaling.

Finally, build resilience by identifying single points of failure. Dual source critical items, prequalify alternative carriers, and keep contingency playbooks for geopolitical, weather, or demand shocks.

In the end, improving supply chain performance is about visibility, focus, and consistent habits. Map the flow, pick the right metrics, align planning, and execute with disciplined data driven routines, then keep iterating.